In addition to the genuine warranty, Milton Roy dosing pump always applies the latest technology in membrane dosing pump.

The materials that make up are also in the best category, giving durability and long usage time.

Easy to replace and maintain. Every 2 – 3 years, just changing the diaphragm at a low price is the pump that can continue to work. Mechanical structure for life of up to 10 years or more.

A special feature of Milton Roy’s pump is the new transmission structure, the deflection wheel. This is the advanced point compared to other pumps.

Below, please summarize the main points of these two types of structures:

1. Feedback spring (Spring Return)

Operating principle:

– Screw rotary motor

– Screw the gear

– Gears turn orange

– Orange push piston forward

– Piston is repelled by springs

– Piston’s travel distance is limited by power adjustment screws

Advantages & Disadvantages:

– Low cost

– Small flow <300 liters / hour

– Flow & pressure increase suddenly, especially with low% capacity setting.

– Flow and pressure fluctuation

– Many damaged parts (orange, piston, power screw, spring)

– Short & light lifespan.

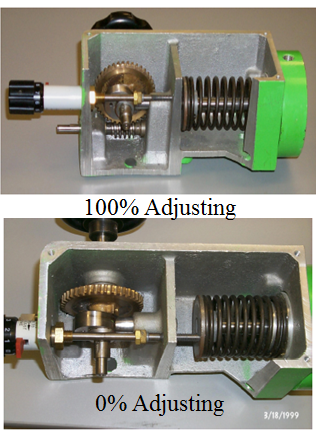

2. Eccentric casters (Eccentric)

Operating principle:

– Screw rotary motor

– Screw gear rotation

-Gear rotating handwheel (handwheel is located between the gears).

-The rotating hand rotates the disc in eccentricity (the hand rotates between the gears)

-Connection on eccentric disc turns circular motion of motor into forward and backward motion of pump diaphragm.

Advantages & Disadvantages:

-High cost

-Stable flow 0% to 100%

– Stable flow and flow

-No wear & damage parts (cams do not push directly into the piston and screws adjust without pressing the spring)

-Long service life, durable, heavy-duty design

-Little maintenance (oil change and bearings only)

-Easy maintenance (screw the screw, pull out the screw to replace the bearing)

Các tin khác